DIVERSIFIED MACHINE INC. 2020 PRODUCT GUIDE

Tech Specs

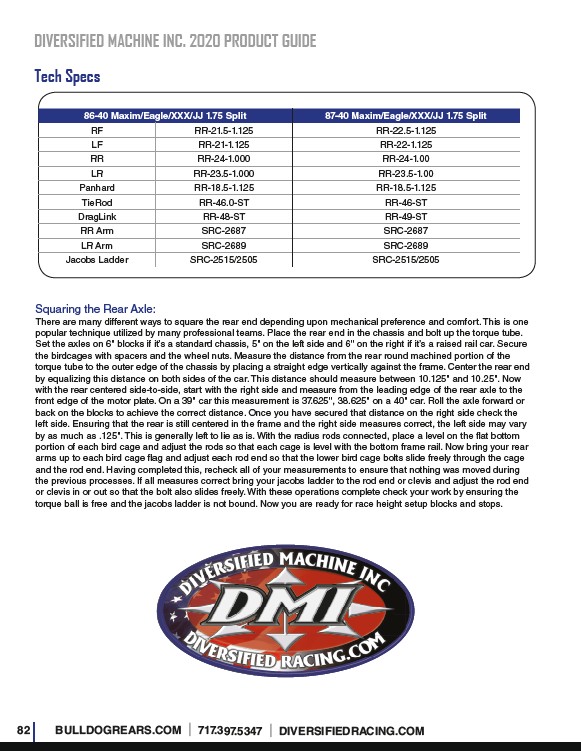

86-40 Maxim/Eagle/XXX/JJ 1.75 Split 87-40 Maxim/Eagle/XXX/JJ 1.75 Split

RF RR-21.5-1.125 RR-22.5-1.125

LF RR-21-1.125 RR-22-1.125

RR RR-24-1.000 RR-24-1.00

LR RR-23.5-1.000 RR-23.5-1.00

Panhard RR-18.5-1.125 RR-18.5-1.125

TieRod RR-46.0-ST RR-46-ST

DragLink RR-48-ST RR-49-ST

RR Arm SRC-2687 SRC-2687

LR Arm SRC-2689 SRC-2689

Jacobs Ladder SRC-2515/2505 SRC-2515/2505

Squaring the Rear Axle:

There are many different ways to square the rear end depending upon mechanical preference and comfort. This is one

popular technique utilized by many professional teams. Place the rear end in the chassis and bolt up the torque tube.

Set the axles on 6" blocks if it’s a standard chassis, 5" on the left side and 6" on the right if it’s a raised rail car. Secure

the birdcages with spacers and the wheel nuts. Measure the distance from the rear round machined portion of the

torque tube to the outer edge of the chassis by placing a straight edge vertically against the frame. Center the rear end

by equalizing this distance on both sides of the car. This distance should measure between 10.125" and 10.25". Now

with the rear centered side-to-side, start with the right side and measure from the leading edge of the rear axle to the

front edge of the motor plate. On a 39" car this measurement is 37.625", 38.625" on a 40" car. Roll the axle forward or

back on the blocks to achieve the correct distance. Once you have secured that distance on the right side check the

left side. Ensuring that the rear is still centered in the frame and the right side measures correct, the left side may vary

by as much as .125". This is generally left to lie as is. With the radius rods connected, place a level on the flat bottom

portion of each bird cage and adjust the rods so that each cage is level with the bottom frame rail. Now bring your rear

arms up to each bird cage flag and adjust each rod end so that the lower bird cage bolts slide freely through the cage

and the rod end. Having completed this, recheck all of your measurements to ensure that nothing was moved during

the previous processes. If all measures correct bring your jacobs ladder to the rod end or clevis and adjust the rod end

or clevis in or out so that the bolt also slides freely. With these operations complete check your work by ensuring the

torque ball is free and the jacobs ladder is not bound. Now you are ready for race height setup blocks and stops.

82 BULLDOGREARS.COM | 717.397.5347 | DIVERSIFIEDRACING.COM