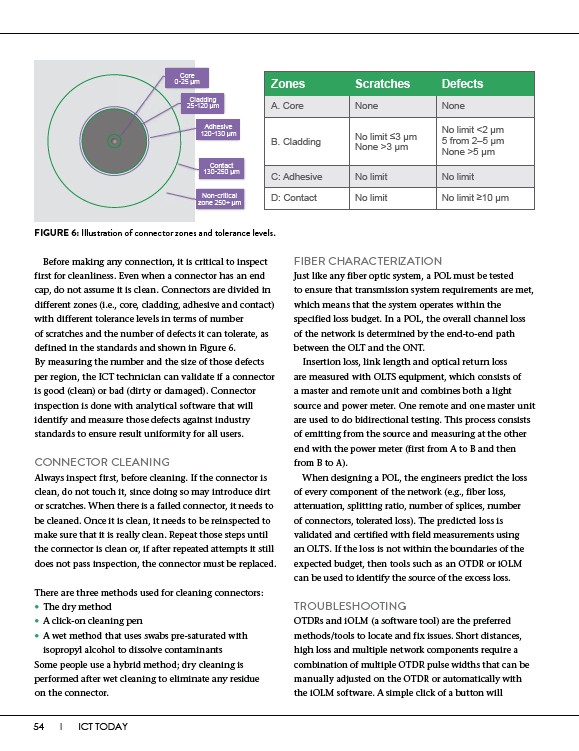

Core

0-25 μm

Cladding

25-120 μm

Adhesive

120-130 μm

Contact

130-250 μm

Non-critical

zone 250+ μm

Before making any connection, it is critical to inspect

first for cleanliness. Even when a connector has an end

cap, do not assume it is clean. Connectors are divided in

different zones (i.e., core, cladding, adhesive and contact)

with different tolerance levels in terms of number

of scratches and the number of defects it can tolerate, as

defined in the standards and shown in Figure 6.

By measuring the number and the size of those defects

per region, the ICT technician can validate if a connector

is good (clean) or bad (dirty or damaged). Connector

inspection is done with analytical software that will

identify and measure those defects against industry

standards to ensure result uniformity for all users.

CONNECTOR CLEANING

Always inspect first, before cleaning. If the connector is

clean, do not touch it, since doing so may introduce dirt

or scratches. When there is a failed connector, it needs to

be cleaned. Once it is clean, it needs to be reinspected to

make sure that it is really clean. Repeat those steps until

the connector is clean or, if after repeated attempts it still

does not pass inspection, the connector must be replaced.

There are three methods used for cleaning connectors:

• The dry method

• A click-on cleaning pen

• A wet method that uses swabs pre-saturated with

isopropyl alcohol to dissolve contaminants

Some people use a hybrid method; dry cleaning is

performed after wet cleaning to eliminate any residue

on the connector.

54 I ICT TODAY

Zones Scratches Defects

A. Core None None

B. Cladding No limit ��3 ��m

None >3 ��m

No limit <2 ��m

None >5 ��m

5 from 2–5 ��m

C: Adhesive No limit No limit

D: Contact No limit No limit ��10 ��m

FIGURE 6: Illustration of connector zones and tolerance levels.

FIBER CHARACTERIZATION

Just like any fiber optic system, a POL must be tested

to ensure that transmission system requirements are met,

which means that the system operates within the

specified loss budget. In a POL, the overall channel loss

of the network is determined by the end-to-end path

between the OLT and the ONT.

Insertion loss, link length and optical return loss

are measured with OLTS equipment, which consists of

a master and remote unit and combines both a light

source and power meter. One remote and one master unit

are used to do bidirectional testing. This process consists

of emitting from the source and measuring at the other

end with the power meter (first from A to B and then

from B to A).

When designing a POL, the engineers predict the loss

of every component of the network (e.g., fiber loss,

attenuation, splitting ratio, number of splices, number

of connectors, tolerated loss). The predicted loss is

validated and certified with field measurements using

an OLTS. If the loss is not within the boundaries of the

expected budget, then tools such as an OTDR or iOLM

can be used to identify the source of the excess loss.

TROUBLESHOOTING

OTDRs and iOLM (a software tool) are the preferred

methods/tools to locate and fix issues. Short distances,

high loss and multiple network components require a

combination of multiple OTDR pulse widths that can be

manually adjusted on the OTDR or automatically with

the iOLM software. A simple click of a button will