7

Chapter 7 Knowing What You Breathe 79

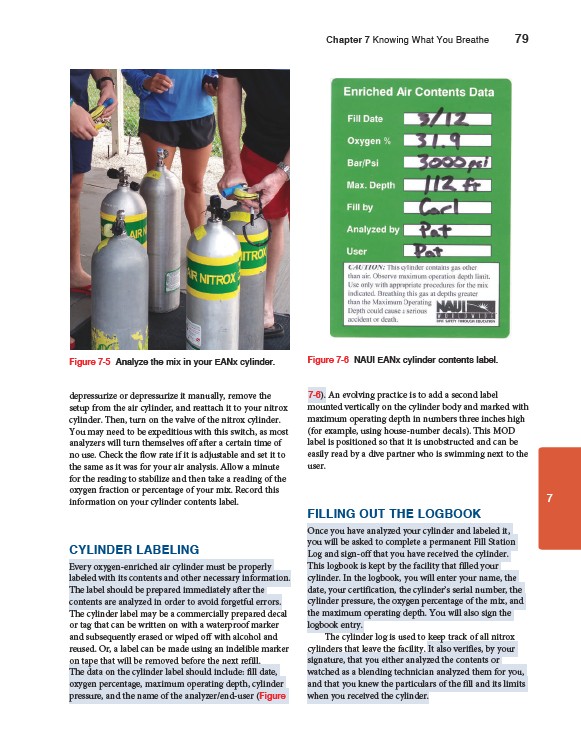

Figure 7-5 Analyze the mix in your EANx cylinder. Figure 7-6 NAUI EANx cylinder contents label.

depressurize or depressurize it manually, remove the

setup from the air cylinder, and reattach it to your nitrox

cylinder. Then, turn on the valve of the nitrox cylinder.

You may need to be expeditious with this switch, as most

analyzers will turn themselves off after a certain time of

no use. Check the flow rate if it is adjustable and set it to

the same as it was for your air analysis. Allow a minute

for the reading to stabilize and then take a reading of the

oxygen fraction or percentage of your mix. Record this

information on your cylinder contents label.

CYLINDER LABELING

Every oxygen-enriched air cylinder must be properly

labeled with its contents and other necessary information.

The label should be prepared immediately after the

contents are analyzed in order to avoid forgetful errors.

The cylinder label may be a commercially prepared decal

or tag that can be written on with a waterproof marker

and subsequently erased or wiped off with alcohol and

reused. Or, a label can be made using an indelible marker

on tape that will be removed before the next refill.

The data on the cylinder label should include: fill date,

oxygen percentage, maximum operating depth, cylinder

pressure, and the name of the analyzer/end-user (Figure

7-6). An evolving practice is to add a second label

mounted vertically on the cylinder body and marked with

maximum operating depth in numbers three inches high

(for example, using house-number decals). This MOD

label is positioned so that it is unobstructed and can be

easily read by a dive partner who is swimming next to the

user.

FILLING OUT THE LOGBOOK

Once you have analyzed your cylinder and labeled it,

you will be asked to complete a permanent Fill Station

Log and sign-off that you have received the cylinder.

This logbook is kept by the facility that filled your

cylinder. In the logbook, you will enter your name, the

date, your certification, the cylinder’s serial number, the

cylinder pressure, the oxygen percentage of the mix, and

the maximum operating depth. You will also sign the

logbook entry.

The cylinder log is used to keep track of all nitrox

cylinders that leave the facility. It also verifies, by your

signature, that you either analyzed the contents or

watched as a blending technician analyzed them for you,

and that you knew the particulars of the fill and its limits

when you received the cylinder.