17

some farming operations in a couple of other

states which led to the need for financing. You

couldn’t go to the bank to get money for this

product. So we went to some capital partners

we worked with in the past, and they were very

interested in being involved in this industry as

well. After six months of discussions, we looked

at being vertically integrated,” said Miller.

Now, don’t be confused – this has nothing

to do with the production marijuana...

The North Carolina Farm Bill of 2019 officially

authorizes and regulates statewide hemp

farming. In 2018, the federal government

removed hemp from its Controlled Substances

Act, which in turn effectively legalized the

cannabis plant. And North Carolina is actively

pursuing the opportunity to help farmers and

make an agricultural impact. In fact, North

Carolina is listed in the “top 10” of the nations

hemp-growing states. Now, don’t be confused

– this has nothing to do with the production

marijuana, the psychoactive cannabis plant

with high THC levels, this is still illegal.

Hemp’s fibers and grains can be used for

a myriad of products, from rope to

sunflower seed oil to the highly beneficial,

industry buzz product of

the moment, CBD.

Abundant Labs has developed

The facility will process and manage

approximately 4,000 lbs of hemp a day.

a new technology for processing hemp

extracts. Their website states, “Our production

team consists of deeply experienced science

professionals with many years of experience

producing industrial hemp products and

in lab management. We use proprietary distillation

methods in production. These methods

allow us to create our products in a manner

that is more efficient than other producers

and also allow us to ensure quality production

throughout the process.” From a production

standpoint, Abundant Labs is excited about research

and development that will be housed at

the home base in Canton, but their main focus

is on the production of high-quality isolates,

specifically the most well known, CBD and also

full spectrum distillates. “When you hear CBD

(an isolate), that’s just one molecule of the

overall plant. We’ll also deliver full spectrum

distillates. As you move through the extraction

process and work the product

into something that people can

use, you narrow what you’re

actually delivering. What we’re

going to narrow down to, from the plant,

is a distillate that just has cannabinoids in it.

And then it might have some terpene, some

things that smell, that kind of stuff,” said Miller.

Research has shown that CBD helps with

inflammation among other ailments. But there

are many other parts of the plant in which the

benefits are still undetermined. “What we do

know from a lot of the studies is the biggest

impact that people see is in a full spectrum

oil that gives them the full impact of what the

plant has, not just one thing, one molecule,”

Miller said.

Abundant Labs’ impressive facility is suited to

produce in a big way. The plant will process and

manage approximately 4,000 pounds of hemp

a day. Miller explained in brewery layman’s

terms, “If you look at a microbrewery and you

compare one to another, our operation would

be like New Belgium and other folks would be

smaller, more like BearWaters in Canton. They

both have a place in the market. They both

have distribution channels. But for us, we’re

going to be processing a lot of material.”

Abundant Labs certainly has made a significant

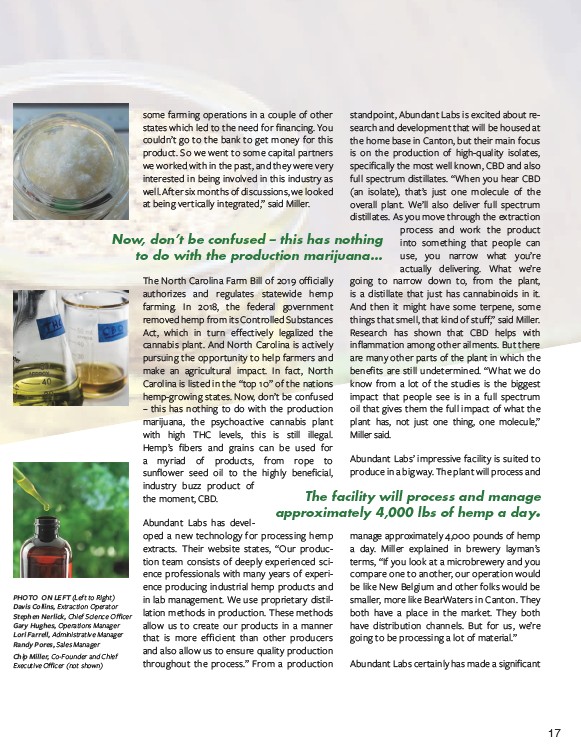

PHOTO ON LEFT (Left to Right)

Davis Collins, Extraction Operator

Stephen Nerlick, Chief Science Officer

Gary Hughes, Operations Manager

Lori Farrell, Administrative Manager

Randy Pores, Sales Manager

Chip Miller, Co-Founder and Chief

Executive Officer (not shown)